What happened to uneven slicing of peanut slicing machine?

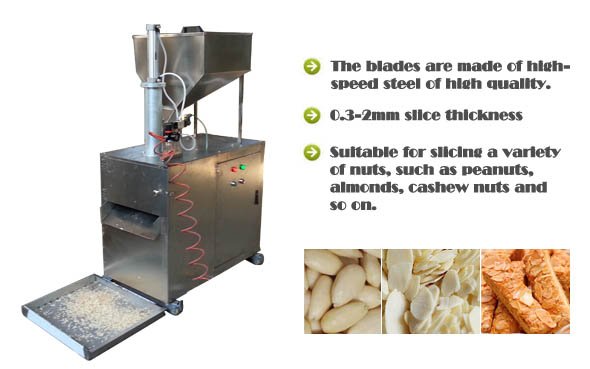

One of the most common operational issues encountered during the use of peanut slicing machines or nut slicers is inconsistent slice thickness. Uneven slicing not only affects the appearance and quality of peanut products but also impacts subsequent processing steps such as roasting, frying, or coating. Understanding the root causes and implementing effective solutions is crucial for maintaining production stability and enhancing overall efficiency.

Below are the key factors contributing to inconsistent slice thickness and their corresponding solutions.

1. Blade problem

The blade is the core component of any nut slicing machine. Its condition has a direct and decisive impact on slicing accuracy. If the blade is dull or damaged, it will result in uneven slicing. It is recommended to check the sharpness of the blade regularly and replace or resharpen it as necessary.

2. Raw material problem

The size and shape of the peanut itself will also affect the slicing effect. If peanuts vary in size or are too dry and wet, it may lead to uneven slice thickness. You can try to screen peanuts to ensure the consistency of raw materials.

3. Improper adjustment of equipment

Incorrect parameter setting of slicer may also lead to uneven slicing. For example, the gap between the blade and the conveyor belt is too large or too small, which will affect the slicing effect. It is suggested that the parameters of the equipment should be adjusted according to the size and demand of peanuts to ensure that the slicer is in the best working condition.

4. Feeding speed problem

If the feeding speed is too fast or too slow, it will also lead to inconsistent slice thickness. By adjusting the feeding speed, peanuts can enter the slicer evenly.

5. Insufficient cleaning of equipment

After being used for a long time, if residues or oil stains accumulate in the equipment, the stability of slicing may be affected. It is recommended to clean the equipment regularly. Clean the peanut slicing machine after each production cycle, paying particular attention to the blades, conveyor belts, and guide components. Establish a routine maintenance and inspection schedule.

6. Technical problem of operators

The familiarity of the operator with the equipment will also affect the slicing effect. If the operation is improper or the key steps are ignored, the quality of slicing may be reduced. It is suggested to strengthen the training of operators so that they can better master the use of equipment.

Uneven slicing thickness in peanut slicing machines typically results from a combination of factors including blade condition, raw material quality, equipment calibration, feed speed, cleanliness, and operator proficiency. Comprehensive addressing of these factors through regular maintenance, proper raw material preparation, precise parameter adjustments, and standardized operation can significantly improve slice uniformity, product quality, and overall production efficiency.

Whether used as a nut slicer, peanut processing equipment, or a multi-purpose food slicing machine, continuous management and optimization are essential for achieving stable, high-quality slicing results.