Efficient filling skills of peanut butter filling machine

With the continuous development of food processing industry, peanut butter, as a condiment deeply loved by consumers, has gradually improved its production efficiency and quality requirements. In a modern peanut butter production line, filling is a key process that directly affects product appearance, weight consistency, shelf life, and overall production cost. Therefore, mastering efficient filling skills and selecting the right peanut butter filling machine are essential for production enterprises.

This article provides a comprehensive analysis of efficient filling techniques for peanut butter filling machines, helping manufacturers improve productivity and ensure stable product quality.

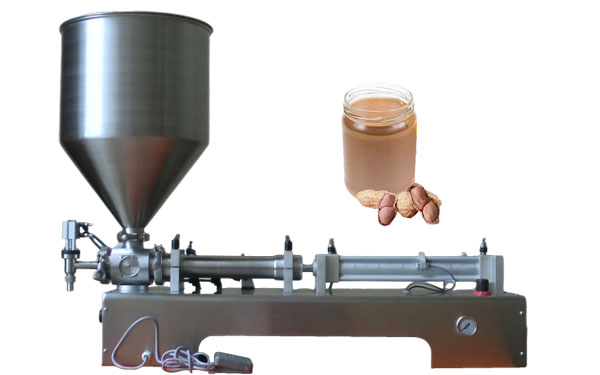

First, choose the appropriate filling machine type. Peanut butter has special requirements for filling equipment because of its high viscosity. When selecting filling machines, priority should be given to equipment specially designed for viscous liquids, such as piston filling machines or screw filling machines. These equipment can effectively avoid the blocking problem caused by material viscosity, and at the same time ensure the accuracy of filling quantity.

Second, optimize the setting of filling parameters. In order to achieve efficient filling, manufacturers need to adjust the equipment parameters according to the characteristics of peanut butter. For example, properly increasing the filling speed can improve the production efficiency, but it is necessary to ensure that there will be no overflow or bubble. In addition, adjusting the filling pressure and temperature is also the key, especially when dealing with peanut butter with different formulas, which should be adjusted slightly according to its fluidity.

Third, regular cleaning and maintenance of equipment. Because peanut butter is a high viscosity material, long-term use may lead to the accumulation of residues in the equipment, thus affecting the filling efficiency and hygiene standards. Therefore, production enterprises should make a strict cleaning plan, thoroughly clean the filling machine regularly, and check whether the key components are worn or broken, so as to ensure that the equipment is always in the best working condition.

Fourth, the use of automated production line. In modern production, the application of automation technology can significantly improve the filling efficiency. Equipped with automatic conveyor belt, intelligent control system and online detection equipment, the integrated operation from filling to sealing can be realized. This not only reduces manual intervention, but also improves the stability of the production line and the consistency of products.

Fifth, staff training and operating norms. Even with advanced equipment, the skills and standard consciousness of operators are still important factors affecting the filling efficiency. Enterprises should carry out regular training to ensure that employees are familiar with the equipment operation process and strictly abide by the safety regulations. At the same time, find and solve problems in time in the production process to avoid the efficiency decline caused by human error.

To sum up, the efficient use of peanut butter filling machine needs to start from equipment selection, parameter optimization, cleaning and maintenance, automation technology and personnel management. By selecting a professional peanut butter filling machine and applying scientific filling techniques, manufacturers can significantly improve production efficiency, ensure accurate filling, and enhance overall product quality.

These improvements not only reduce operational costs but also strengthen competitiveness in the global peanut butter market, laying a solid foundation for long-term business growth.