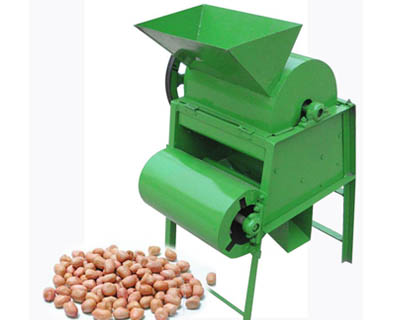

Selection of peanut shelling machine

Requirements for peanut shelling machine for sale: clean shelling and high productivity. For peanut sheller with clear selection device, it also requires higher degree of cleanliness. The loss rate and breakage rate should be low; the structure should be simple, reliable, easy to adjust, less power consumption and certain versatility. It can be used in a variety of crops shelling to improve the utilization rate of the machine.

Matters needing attention in using peanut sheller:

1. Please place the sheller in a spacious and flat place for operation.

2. According to the different sizes of shelled peanuts, select the matching screen for shelling.

3. When the machine is running, please don't put your hand into the motor, blower, the inside of the shield and the deep part of the feed inlet to avoid injury.

4. The width of the feed inlet is generally adjusted to about 3.5 cm (it can be appropriately adjusted according to the size of peanut varieties), and the peanut should be fed evenly when it is shelled.

5. When assembling the vibrating screen, tighten the pull rod nut at the bottom of the vibrating screen, and the length of the pull rod tail is generally 2 cm.

6. If the shelled peanuts are too dry, the breakage rate will increase correspondingly when they are shelled. At this time, the peanut shells can be soaked evenly with clear water and placed for several hours before shelling, and the effect can be achieved.