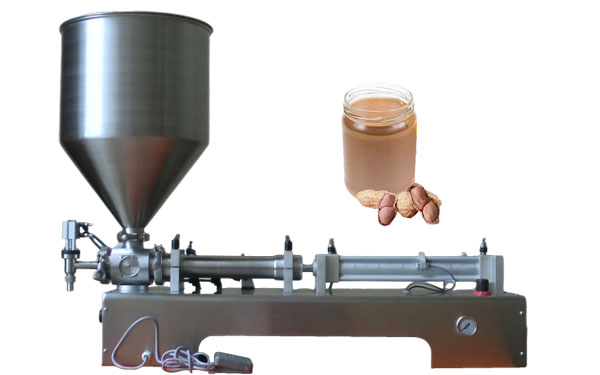

How to choose a suitable peanut butter filling machine according to production volume?

With the continuous development of the food processing industry, the demand for peanut butter, a common condiment, is growing year by year. The choice of peanut butter filling machine is crucial in the production process, impacting not only production efficiency but also product quality and cost control.

So, how to choose the suitable peanut butter filling machine based on your production volume?

1. Clarify your production volume requirements

First, you need to clearly define your production scale and daily output targets. For example, a small business may need to fill a few hundred bottles of peanut butter per day, while a large factory may produce tens of thousands of bottles. Therefore, production volume is the primary consideration when selecting a filling machine. If your production volume is low, you can choose a semi-automatic filling machine, which is easy to operate and low-cost, making it suitable for small and medium-sized businesses. For higher production volume, consider a fully automatic filling machine to meet your production needs.

2. Consider the equipment performance

Different types of peanut butter filling machines have different performance characteristics. For example, peanut butter is a highly viscous material, so the filling machine requires strong pumping capacity and precise metering capabilities. Some high-end equipment is also equipped with anti-drip devices and automatic cleaning functions, which can effectively reduce the waste and improve the production efficiency. When selecting, the filling speed, accuracy and stability of the equipment should be evaluated according to the production requirements.

3. Consider the scalability of your equipment.

As your business grows, your production needs may increase. Therefore, when selecting a filling machine, consider its scalability. For example, some filling machines can increase capacity by replacing components or adding modules. This flexibility can help save on future upgrade costs.

4. Cost and budget

Budget is also an important factor in choosing a filling machine. Semi-automatic equipment is less expensive but requires manual intervention. Fully automatic equipment, while more expensive, significantly reduces labor costs and improves production efficiency. Choose the equipment that offers the best value based on your budget and expected long-term returns.

5. After-sales service and maintenance

Last, pay attention to the manufacturer’s after-sales service. Peanut butter filling machine may malfunction over time, so choosing a manufacturer that provides excellent after-sales service is crucial. Equipment maintenance costs are also a factor to consider.

Choosing the right peanut butter filling machine for your production volume requires comprehensive consideration of factors such as production needs, equipment performance, scalability, budget, and after-sales service. Only by choosing equipment that meets your needs can you achieve efficient production while ensuring product quality, ultimately generating greater economic benefits for your business.