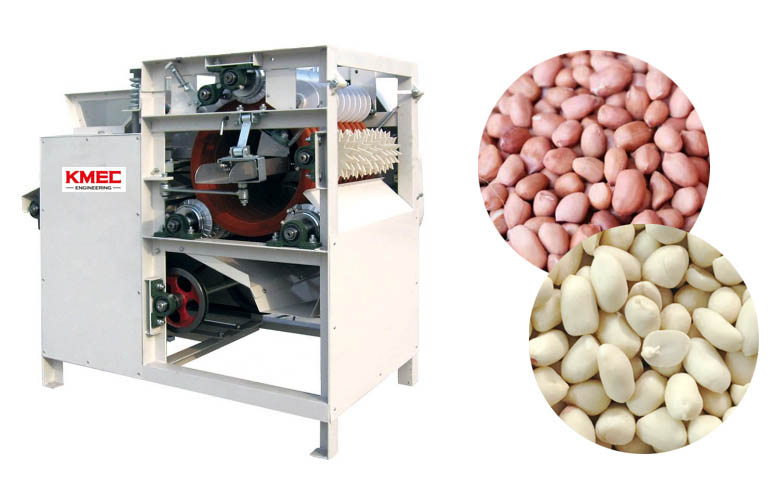

Main peeling structures of wet type peanut peeling machine

Peanut peeling machine is a common equipment in peanut processing, which can usually be divided into dry type peanut peeling machine and wet type peanut peeling machine. Today, let’s learn about the main peeling structures of wet type peanut peeling machine.

The main peeling structures of wet type peanut peeling machine are as follows:

1, Feed conveying system: The feed conveying system of the wet type peanut peeling machine is responsible for conveying the peanuts to be peeled from the feed inlet to the peeling cavity. Usually, a belt or chain transmission system is used to ensure that the peanuts can be continuously and smoothly conveyed during peeling.

2, Water spraying system: Water spraying system is an important part of wet peeling process. It sprays water evenly on the surface of peanuts, making the skin soft and easy to peel off. Water also helps to wash away any skin or debris that may accumulate in the chamber during peeling. The water spraying system aims to ensure that a proper amount of water is sprayed into the room to achieve the best peeling effect.

3, Peeling cavity: Peeling cavity is the core component of wet type peanut peeler machine, which mainly includes rotor, stator and shell. The rotor is a rotating assembly, on which peeling tools such as blades or brushes are installed, and peanut skins are removed by high-speed rotation. The stator is a fixed component, which is fixed in the shell and works with the rotor to ensure the stable movement track of peanuts in the peeling cavity.

4, Unloading system: The unloading system is responsible for collecting peeled peanuts and unloading them from the machine. It aims to ensure that all peeled peanuts are collected and no peeled peanuts are discharged. Depending on the design of the machine, the unloading system can be a conveyor belt or a chute.

5, Control system: Wet type peanut peeling machine is usually equipped with an intelligent control system, which is used to set and monitor the operating parameters of the equipment, such as feeding speed, water spraying amount and rotor speed. By setting these parameters reasonably, we can adjust the peeling effect and improve the peeling quality according to different types and sizes of peanuts.

The main peeling structures of wet type peanut peeling machine are composed of feed conveying system, water spraying system, peeling cavity, discharging system and control system. The structure of each part of the equipment closely cooperates and interacts to ensure the peeling effect. The feeding conveying system smoothly sends peanuts into the peeling cavity, the water spraying system softens the skin, the rotor and stator in the peeling cavity work together to peel the skin, and finally the unloading system is responsible for collecting peeled peanuts and unloading them from the machine. Through the intelligent adjustment of the control system, the stable and reliable operation of the equipment is ensured, and flexible operation is carried out according to the actual needs.

Wet peeling is the most popular and effective technology in industry, and wet type peanut peeling machine is an important equipment for peanut processing. The main design of wet type peanut peeling machine can realize efficient and effective peanut peeling, which is inseparable from the work of each system of the machine.