The Essential Role of Peanut Sieving Machines in Modern Peanut Processing

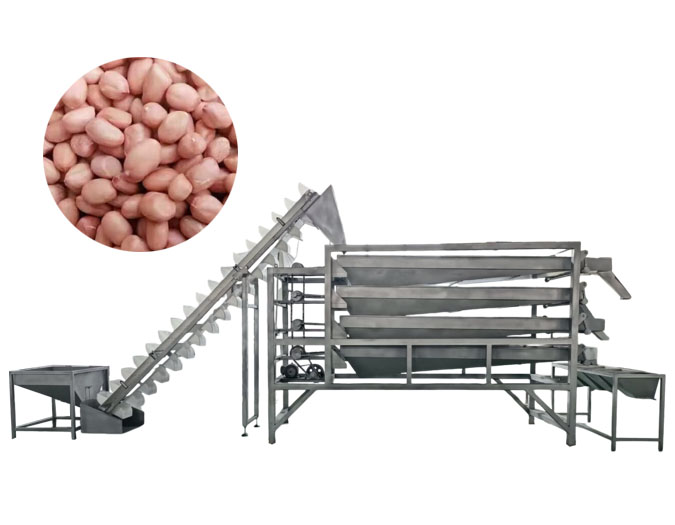

In today’s agriculture and food processing industries, mechanized equipment has revolutionized production, enabling higher efficiency, consistency, and quality. Among these innovations, the peanut sieving machine stands out as a critical piece of peanut processing machinery. This specialized equipment streamlines the cleaning, sorting, and grading of peanuts, delivering tangible benefits to producers and processors alike.

The Essential Role of Peanut Sieving Machines

1. Peanut sieving machine can significantly improve the processing efficiency.

In the traditional manual screening, it is time-consuming and labor-intensive and inefficient, especially in the face of large quantities of peanuts, manual operation is difficult to meet the demand. The peanut sieving machine can quickly complete the cleaning, grading and screening of peanuts through automatic operation, which greatly shortens the processing time and reduces the labor cost.

2. Peanut sieving machine can effectively improve product quality.

Peanuts are often mixed with dirt, stones, immature fruits and other impurities after harvest. Through the multi-layer screen and grading system of the peanut sieving machine, these impurities can be quickly separated to ensure the purity of the final product. In addition, the peanut sieving machine can also classify peanuts according to their size, weight and other parameters, which makes the processed peanuts more in line with market demand.

3. The use of peanut sieving machine also helps to reduce the waste of resources.

Traditional manual screening is easy to miss or repeat screening, while mechanized equipment can accurately complete each step, reducing the losses caused by improper operation. This will not only help enterprises to reduce costs, but also reduce the negative impact on the environment.

Key Features of Modern Peanut Sieving Machines

Today’s peanut processing machines are designed with advanced features to meet diverse industry needs:

- Multi-Layer Screening: Enables simultaneous removal of debris and grading by size.

- Adjustable Settings: Allows operators to customize sieve sizes and vibration intensity based on peanut variety and processing goals.

- Durable Construction: Built from food-grade materials, these machines are corrosion-resistant and easy to clean.

- Energy Efficiency: Modern designs prioritize low power consumption without compromising performance.

Applications Across the Peanut Industry

Peanut sieving machines are versatile and widely used in various stages of peanut processing:

- Pre-Cleaning: Removing large debris and foreign materials after harvesting.

- Grading for Roasting and Packaging: Sorting peanuts by size to ensure even roasting and attractive packaging.

- Processing for Peanut Butter and Oil: Delivering clean, uniform nuts for further processing into value-added products like peanut butter and oil.

To sum up, peanut sieving machine plays an indispensable role in peanut processing. It not only improves production efficiency and product quality, but also saves costs for enterprises, which is an important embodiment of the development of modern agricultural mechanization. With the continuous progress of science and technology, it is believed that the peanut sieving machine in the future will be more intelligent and bring more convenience and benefits to the peanut industry.